Printing on Cotton/ Spandex Blends

In this installment of the Impressions Tech Tips Newsletter, we will review printing specifications for the American Apparel Cotton Spandex Jersey Crop Top, style 8379. The 40/1 combed cotton/Spandex construction refers to fabric that is knit with very thin thread. Yarn is referenced with regard to the fineness of the thread. A spool of thread used to knit a cotton T-shirt will have about 840 yards of cotton thread on it.

From this point, the number of spools required to weigh one pound of yarn is determined. If it takes 30 spools of thread to weigh one pound, the fabric knitted with that yarn would be referred to as a 30/1, or 30-singles fabric. In that phrase, 30 refers to the number of spools required to equal 1 pound, and singles refers to the yarn being comprised of one individual thread. Thus, if 20 spools were required to equal 1 pound, the fabric would be referred to as 20-singles. Likewise, 40 spools would be referred to as 40-singles. The higher the yarn count, the thinner the thread.

The 40-singles construction of the fabric being used for the purposes of this newsletter enables an exceptionally smooth surface, thus simplifying the screen printing process.

The fabric weight to which you often hear your apparel wholesale representative or manufacturer refer (such as 5.5- or 6-ounce fabric) is the amount of knitted fabric required to make 1 square yard. Most textile screen printers use this to judge how thick the fabric actually will be. Most apparel tops are referred to in weights ranging from 4 ounces to 13-plus ounces. This all is dependent on the fabric knit and content.

The fabrics used today are manufactured in increasingly lighter weights while using new and different fabric combinations. This American Apparel style contains a 95% combed cotton/5% spandex combination. The combed cotton (as opposed to standard cotton) refers to a process where the shorter fibers and residual impurities are removed from the cotton. This gives the knitted fabric a softer and smoother surface for printing and a stronger, more durable fabric since the shorter cotton fibers have been removed from the spinning process.

The 5% spandex fabric offers the most interesting aspect of this particular garment. From the description, there seems to be a very small amount, but it gives the fabric a huge amount of elongation — an estimated 25% more than standard cotton tees. As this garment is a ladies style, additional elongation offers the form-fitting characteristics that are so popular today.

PRINTING CONSIDERATIONS

As this garment features a V-shape cut, we used a 10- inch platen that will allow all the adult sizes to be easily loaded. A 14- or 16-inch platen will require stretching the garment, resulting in the printed graphic potentially being distorted.

In addition to helping ink films withstand exertion due to additional stretch, most high-elongation inks cure at lower temperatures. Spandex/elastane is a heat-sensitive fabric and could react to prolonged exposure to high temperatures. A low-temperature, high-elongation ink will allow you to avoid any such complications during the production process.

Although synthetic dye migration always is an issue when printing on a synthetic fabric such as polyester, the same does not hold true for spandex/elastane. Although it is a synthetic fabric, it typically will not exhibit bleeding (dye migration) issues in the same manner as polyester.

Spandex fibers will retain synthetic dyes within the fiber and deter dye migration much better than polyester fibers. Should you decide to print with high-elongation plastisol ink, check with your manufacturer to ensure it has bleedresistant characteristics.

When determining printing parameters, screen mesh counts are important. When working with a fabric such as 40-singles, 95% cotton/5% spandex, keep in mind the very tight knit and thin thread that comprises the fabric. This allows you to print with thinner-than-usual ink films, as your ink penetration into the fabric will be minimized. This means you can use finer screen mesh counts.

In this scenario, I printed the garments with a 156 mesh. When printing light-colored (white, in this case) ink onto a dark fabric, most printers would employ a 110 mesh to ensure good matte and opacity. If printing a multicolor graphic on this fabric, you could easily use a 305 mesh count for either printing onto an underbase or wet-onwet onto the virgin fabric itself. As usual, I prefer to use a high-tension screen that will only complement the fabric and process.

The tight nature of the fabric surface allows the ink to ride on it, which offers a number of different benefits besides the higher mesh count. These include

- Hand The thinner ink film produced through the higher mesh count will have a softer hand, which is more desirable when working with lighter weight fabric of this nature.

- Flash Cure The thinner ink film (when printing as an underbase) will flash faster, as you are gelling a thinner ink film that will be laying on the fabric’s surface. In addition, when printing low-temperature stretch ink, you can decrease your flash unit’s output, as you are gelling at a lower temperature. Always pretest to ensure the flashing procedures and temperatures are optimized for your particular printing scenario.

- Elongation As thinner ink films lend themselves to easier flashing and curing parameters, the highelongation inks also will perform better in a thinner printed ink film as opposed to a thicker one. Thicker ink films require more heat to properly flash and cure and, thus, run the risk of stretching when cured.

SQUEEGEES & CURING

The preferred squeegee selection for this fabric-printing scenario would be a 70/90/70 triple-durometer blade that will allow the softer edge to transfer the desired ink amount onto the fabric surface. For the printing of the samples in this sequence, I used a standard 70-durometer squeegee. A squeegee that is too hard will over-shear the ink film and deter the ink’s opacity. And if the squeegee is too soft, you will deposit an excessive ink film that will deter the previously mentioned benefits.

Since we are working with a low-temperature ink to minimize any spandex shrinkage, it is important to make the appropriate adjustments to not only the flash unit, but also the dryer. As infrared dryers do not offer the degree of control that gas-fired, hot-air dryers do, it is important to make your initial adjustments and then test to ensure your are reaching the proper cure.

I have reviewed different heat-monitoring devices in the past that can determine dryer temperature. These include heat tapes, non-contact pyrometers and donut probes. Although all three are suitable for determining dryer temperature as quality control devices, the true test is to test wash a sample to ensure the ink is properly cured.

Although many printers would shy away from the thought of printing onto specialty fabrics, the cotton/spandex blend actually eases the process for those striving to achieve quality prints. The thin thread used in the fabric’s construction, in conjunction with the tight knit of the finished fabric, make the 95% cotton/5% spandex blend an extremely printer-friendly fabric.

step-by-step

-

Step1: The American Apparel Cotton Spandex Crop Top is a 5.6-ounce-per-yard, 40-singles fabric.

Step1: The American Apparel Cotton Spandex Crop Top is a 5.6-ounce-per-yard, 40-singles fabric. -

Step2: The 40-singles, combed cotton construction gives the fabric an exceptionally smooth surface, making it excellent for screen printing.

Step2: The 40-singles, combed cotton construction gives the fabric an exceptionally smooth surface, making it excellent for screen printing. -

Step3: This shows medium-sized garment loaded onto the 10-inch platen. This allows enough room to easily load a small size as well.

Step3: This shows medium-sized garment loaded onto the 10-inch platen. This allows enough room to easily load a small size as well. -

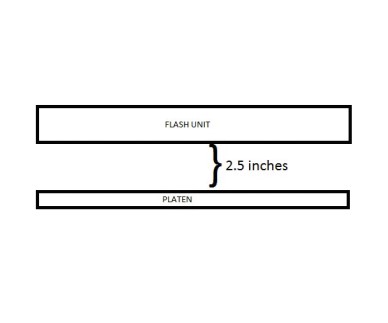

Step4: In this scenario, we raised the flash unit to 3.5 inches to minimize the heat exposure to the flash unit. The ink film flashed in 4.5 seconds.

Step4: In this scenario, we raised the flash unit to 3.5 inches to minimize the heat exposure to the flash unit. The ink film flashed in 4.5 seconds. -

Step5: This shows the image printed with a 156 mesh and double stroked for maximum ink coverage.

Step5: This shows the image printed with a 156 mesh and double stroked for maximum ink coverage. -

Step6: This shows the ink film being stretched 200% with no cracking or separation to the ink film.

Step6: This shows the ink film being stretched 200% with no cracking or separation to the ink film.