Printing on Tri-Blended Apparel

Due to the light fabric weight, it is more important than ever to minimize the ink film of the embellishment in order to maintain a soft hand.

In this Impressions Tech Tips Newsletter, we will look at four of the different fabric configurations, and the different embellishment processes to which they lend themselves. American Apparel introduced its first tri-blend fabric in 2006, with a 50% cotton/25% polyester/25% rayon construction. The general fabric has a tight knit, its weight varies based on the garment style and it exhibits minimal shrinkage.

Aside from the fabric weight, it’s important to remember the varying rayon content in tri-blend fabrics because it can be sensitive under different heat sources. Caution must be taken during the flashing and curing processes to ensure a proper ink film cure, while not causing the rayon to be adversely affected by the heat source.

1. TRI-BLEND OATMEAL (STYLE TR401)

3.7-OUNCE TRACK TEE

The fabric content of this garment is 50% polyester/37% ring-spun cotton/13% rayon. This description alone should tell you a good bit about your embellishment options. The first consideration should be the fabric weight. Many of the latest fashions are being produced in lighter weight fabrics for comfort and style. The fabric weight dictates that we employ the thinnest ink film possible to maintain a soft hand. It would be very easy to overpower a fabric of this weight when printing with plastisol ink. Thus, some conventional printing methods may need to be revisited in order to achieve the desired effect.

We will be reviewing two primary printing methods that can be used while maintaining a soft hand. This includes soft-hand plastisols printed through finer mesh counts and high-opacity water-based or discharge inks.

Because this garment is a 3.7-ounce-per-yard fabric, keep your ink film as thin as possible. Since we are printing on an oatmeal garment in this case, potential dye migration will not be an issue. However, if we were printing on a darker fabric, it would be ideal to print with a bleed-resistant plastisol ink to minimize the potential for dye migration.

Although high-opacity water-based ink will work with this fabric, we used discharge ink in this case. The aspect of discharge ink to remember here is that only the cotton portion of the fabric will discharge, as this ink type will have no effect on the dyes used on the synthetic polyester or rayon. The result will be a vintage, washed appearance that is quite popular today. The garment was printed with a 156 mesh count on all screens.

However, if you are shooting for a brighter, more vibrant print, use soft-hand plastisols. This holds especially true on darker shades, but remember to also use a bleedresistant underbase. Recommended mesh counts for printing plastisols on this fabric in dark shades would be:

- White Underbase: 230 to 156 mesh (maximum)

- Flash

- Color: 230 mesh

- Color: 230 mesh

- Color: 230 mesh

- Flash

- Highlight White: 230 mesh

It also would be beneficial to use high-tension screens, which would ensure minimal penetration of the ink film into the fabric. Rather, the print would stay on the surface and dye migration from the fabric’s polyester content would be minimized.

2. TRI-BLEND RIB

5.9-OUNCE PULLOVER RAGLAN

This garment is composed of 50% cotton/25% polyester/25% rayon and has the fabric weight of most high-end heavyweight T-shirts. The general surface is tight and ribbed, but the fabric construction is such that screen printers can use more traditional methods without worry that the print would overpower the fabric. The ribbed construction is tight enough that standardized ink films still will deposit smoothly onto the fabric surface. I still recommend printing the softest hand possible when working with plastisols, so using a soft-hand additive will only increase the softness of the print.

Also, remember that you’re working with fabric that includes 25% rayon content. This will give the garment excellent stretching characteristics. In order to address this from a plastisol printing standpoint, you may consider adding 10%-15% of a high-elongation base to allow for the additional stretch that the rayon content enables.

3. TRI-BLEND FLEECE TERRY ZIP JACKET

9.2-OUNCE-PER-YARD2 (STYLE TRT497)

This garment contains a 50% polyester/42% cotton/8% rayon fabric content with a terry knit surface, which is smooth and even for easy application of either a plastisol or discharge print. The 8% rayon will give the fabric good elongation without jeopardizing the performance characteristics of a plastisol ink film.

As with the printing application of any fleece, you will have a greater amount of fabric compression due to the garment’s soft nap. Thus, you should print as thin of an ink film as possible, since the fabric compression will allow a greater amount of ink to transfer to the surface than when printing on, say, a jersey knit. You can print with the previously mentioned mesh counts, with the exception of using a 156 mesh for the underbase.

Remember to also take caution with your flashing procedures, as the fabric’s rayon content will be sensitive to the extreme temperatures exerted by the flash unit. This could result in slight shrinkage on the press. In these cases, consider decreasing your flash temperature in order to minimize this effect

4. STANDARD TRI-BLEND JERSEY TANK

The 50% cotton/25% polyester/25% rayon jersey tank falls under the same printing parameters as the 3.7-ounce oatmeal track tee. The primary difference here is that we are actually printing on a dark shade, as opposed to the lighter oatmeal shade that we previously printed.

Again, due to the fabric’s lightweight characteristics, producing the softest hand possible is paramount. It is here that, if printing a white underbase for color overprinting, you should use a bleed-resistant stretch white. This will ensure any potential dye migration issues with the polyester content will be minimized, while also allowing for the elongation required to address the 25% rayon content.

When printing with plastisol ink, ensuring your screens are as tight as possible on all fabrics mentioned herein will only contribute to producing the softest print possible on the fabric surface. Also, conduct flashing tests when printing darker shades. The rayon content of the tri-blend fabrics will allow the fabric to be susceptible to potential shrinking from the flash units. Fused quartz flash units are known for this; thus, you should work with your temperature setting, distance and dwell time to ensure you are achieving the desired gel point for your ink film while not adversely affecting the fabric.

Step 7 (below) is a good example of the muted, vintage effect you can achieve when printing onto a partially synthetic fabric with a discharge effect. Also, you always should perform preliminary tests when printing with highopacity water-based discharge inks to ensure the desired results.

As the popularity of tri-blend fabrics grows, the need to control your ink parameters and ink film thickness will only follow suit. Whenever you print a new fabric with any ink, retain a production sample to ensure consistent results between production runs.

Step-by-Step

-

Step1: This tri-blend garment was printed with slightly extended soft-hand plastisols through 230 mesh counts using a hard, sharp squeegee. Remember to minimize the plastisol ink film on such fabrics. When printing waterbased or discharge ink, it will penetrate into the fabric, thus producing a softer hand. Printing courtesy of Reliable Custom Imprints, Longwood, Fla.

Step1: This tri-blend garment was printed with slightly extended soft-hand plastisols through 230 mesh counts using a hard, sharp squeegee. Remember to minimize the plastisol ink film on such fabrics. When printing waterbased or discharge ink, it will penetrate into the fabric, thus producing a softer hand. Printing courtesy of Reliable Custom Imprints, Longwood, Fla. -

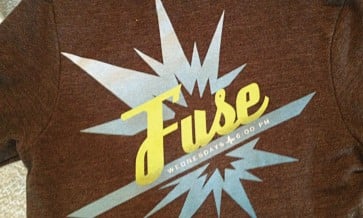

Step2: This print shows the results of using discharge ink on tri-blend fabric. Due to the light shade of the oatmeal fabric, the print is bright, vibrant and has a very soft hand. Printing courtesy of Real Thread, Winter Park Fla.

Step2: This print shows the results of using discharge ink on tri-blend fabric. Due to the light shade of the oatmeal fabric, the print is bright, vibrant and has a very soft hand. Printing courtesy of Real Thread, Winter Park Fla. -

Step3: Shown here is a white, bleed-resistant ink film printed onto the surface of the fabric. Recommended mesh counts for this garment would be a 156 mesh for the underbase and a 200 mesh for the second white, when printing with plastisol. Printing courtesy of Reliable Custom Imprints, Longwood, Fla.

Step3: Shown here is a white, bleed-resistant ink film printed onto the surface of the fabric. Recommended mesh counts for this garment would be a 156 mesh for the underbase and a 200 mesh for the second white, when printing with plastisol. Printing courtesy of Reliable Custom Imprints, Longwood, Fla. -

Step4: Shown here is an allover discharge print. All colors were printed through a 156 mesh, allowing for the halftone detail seen in the text. Printing courtesy of Real Thread, Winter Park, Fla.

Step4: Shown here is an allover discharge print. All colors were printed through a 156 mesh, allowing for the halftone detail seen in the text. Printing courtesy of Real Thread, Winter Park, Fla. -

Step5: Water-based discharge effects on a tri-blend fleece allow for a bright print while producing a minimal hand on the fabric surface.

Step5: Water-based discharge effects on a tri-blend fleece allow for a bright print while producing a minimal hand on the fabric surface. -

Step6: Shown here is bleed-resistant white, which includes an underbase (printed through a 156 mesh), flash and then overprint through a 200 mesh. Printing courtesy of Reliable Custom Imprints, Longwood, Fla.

Step6: Shown here is bleed-resistant white, which includes an underbase (printed through a 156 mesh), flash and then overprint through a 200 mesh. Printing courtesy of Reliable Custom Imprints, Longwood, Fla. -

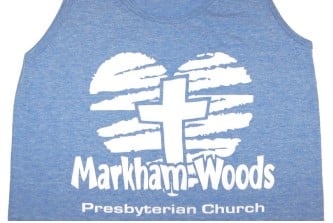

Step7: Here you see the muted effect that the fabric’s polyester and rayon content can have on a water-based discharge print. Printing courtesy of Real Thread, Winter Park, Fla.

Step7: Here you see the muted effect that the fabric’s polyester and rayon content can have on a water-based discharge print. Printing courtesy of Real Thread, Winter Park, Fla.